Into The Woods 2021

Technical Stage Department

Flys & Automation

Head of Flys & Automation: Darren Wilson

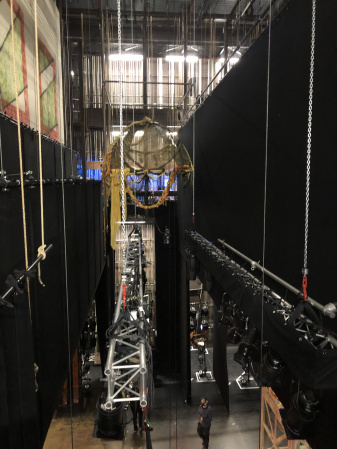

The flown set pieces for this show consisted of a large canopy that would fly in and land over the top of a 5m tower and 4 metal framed shards, 2 of which needed to be able to track across the stage and the other 2 which only needed to be able to fly in and out.

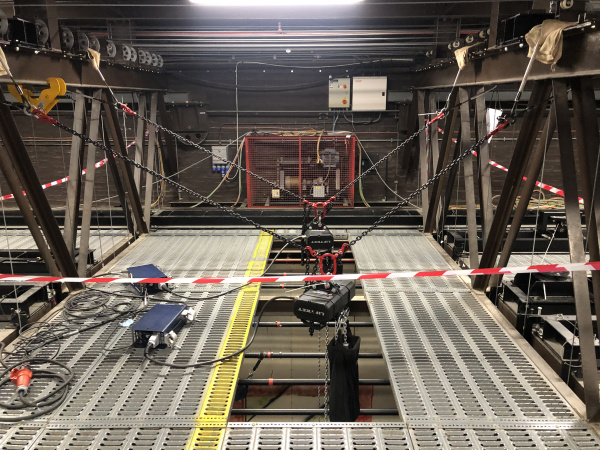

Due to the position of the canopy, counterweight bars 6 to 12 needed to stay gridded to ensure there was enough overhead space for the canopy and its dressing to fly fully out of view. For LX it was decided that the bulk of their overhead requirements in this area would be rigged on two 7m truss spans, SL of the canopy, these would be rigged on the Kinesys Liftket Hoists. SR of the canopy there would also be two small drop bars, one on CW 9 and the other on 12. To install the two centre stage Kinesys hoists we needed to remove grid panels as the points were on bridles.

On CW 11 there was a kabuki drop effect for Cinderella’s dress, this was rigged on a small drop bar that could be raised and lowered from prompt side, this meant that the canopy frame wouldn’t have to be lowered in to the stage every time we needed to reset the kabuki drop. The kabuki drop was also controlled from prompt side.

There was enough height for the canopy to have around 4m of dressing however when props dressed the canopy in the venue only around 2m was added.

-

LX truss

-

Grid Panels Removed

-

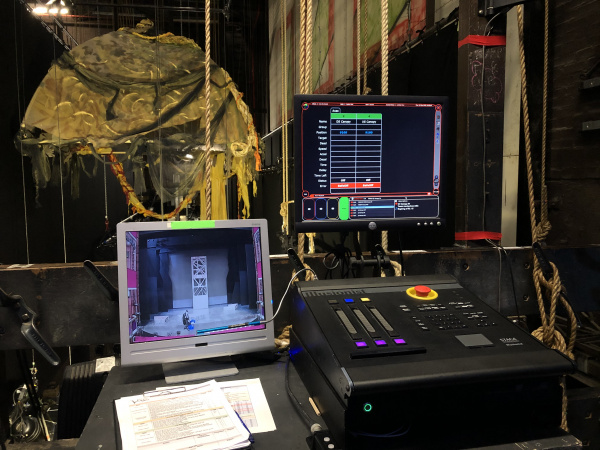

Control Desk

Flys & Automation Cue Sheet

Pre Show Checks

Fly & Hemp Plot

Automation Plot

Automation Cue Sheet (Exported from desk)

Deads List (Exported from desk)

Flown Set Piece Info

Canopy Plan

Points Plan

Points Master

Grid Plan

The grid was particularly busy with hemp points for this show using every single possible bit of hemp there was.

Set

Head of Stage: Noah Dates

The set elements on the ground consisted of three green framed flats, 3 low tiled platforms and a 5M, 500KG tower.

The green framed flats used regular castors to move about the stage and were secured in their positions using frictions brakes. Due to the amount of wood on the frames, the smallest flat was top heavy. In order to solve this issue, flyweights were added to the bottom on the opposite side of the flat to keep the structure stable.

For the low tiled platforms, carpet tiles were attached to the bottom for movement across stage. Originally, they used furniture sliders. However, due o the weight of the platforms, they quickly compressed and caused scratches on the floor. The carpet tiles were decided on as a fallback option.

For the tower, castors which utilized CO2 were used. The CO2 was ordered and put in place after the castors and the hoses were installed and threaded through the bottom of the set element. The tank and the hardware needed for hooking up the hoses was hidden inside the tower. In order to brake the tower and turn the pressure on and off at the beginning and end of the day, we needed access to the switch and the tank. A hole was drilled into the side of the tower, where the switch was threaded through for easy access. it was placed on the underside of the crossbeam in an attempt to mask it to the best of our ability. The treads on the tower doubled as a door which opened with pin hinges to give us access to the tank.

The tower also had a rope swing coming from the first floor. An eye bolt was put in place and the rope swing was tied on and secured every day by the Head of Stage using a figure of nine knot. The eye bolt was am M12 and it was positioned in the floor of the first floor. It was angled towards the physical movement in order to give it the most strength possible to ensure the performer's safety. The know was tied with artificial hemp that was woven into the hair in order to give a secure line for the performer to swing around on.

Stage Management

Lighting

Sound

Team

Sound Designer/Snd no.1 (SD) - Stuart Henderson

Production Sound Engineer (PSE) - Corey Jackson

Sound No.2 - Stuart Green

Sound No.3 - Lewis Brown

Design

Plan

Equipment List

Band Layout

Due to the restrictions on distance due to the ongoing pandemic we had to prove that the band would all fit into the pit safely. To do this our PSE created a plan of the pit and then placed each performer in their individual bubble showing clear 2 meter spacing between all 7 members of the band.

Cable Runs

Full Venue cable run

Control room to FOH cable run

Sound World Postion

Due to limited capacity on stage Sound World for ITW 2021 could not be on stage. This meant that it was built in the control room. This actually turned out to be a largely convenient place for it. As we were using the Dante network it made it would be easy to patch throughout the venue as the patch points were located next to the Racks. it also meant the PSE and SND No.1 Could stay in contact throughout the show.