Stage Technologies Installation

Installation of Stage Technologies Power Flying System

Monday 31st March - Day 1

The gear arrived on Friday 28th March when I was on holiday, when I arrived in at 9am on Monday the stage looked like a dumping ground with winches, monitors , bags of mysterious bits along with all the RSAMD LX lantern stock, cables and multicores “laid out” for PAT testing. Also, for whatever reason, the preparations that I had been promised for the Stage Tech installation week hadn’t happened.

Luckily the engineer and project manager had decided to fly up on Monday morning and wouldn’t be arriving until 11am, so Richard, Steven and I began preparing for the install. By 11am a section of grid on stage right had been removed and wearing the rope access harnesses clipped off to anchor points as fall restraint we were ready.

An initial bridle was rigged over the missing floor section and the chain of the chainhoist hauled up on rope. It was attached and the chainhoist then climbed itself to the maximum height possible with one of the girder beam. The idea was that once the first girder beam was at grid level we could span it between the upstage downstage structural supports and create a new higher chain hoist anchor point for the remainder of the gear. With a bit of difficult maneuvering we managed to get the beam in position just as Andrew and Charlie arrived.

With the chain hoist now anchored to the overhead I-beam spreader we continued on with the next 3 beams until lunch, the extra height of the anchor point making beams 2, 3 & 4 much easier. After lunch i needed to attend a meeting and when I got back 3 or the four winches were already on the grid. The winches weigh about 130kg each and are a bit top heavy proving to be quite and handful when trying to swing them from the middle of the grid section to a safe point for detachment.

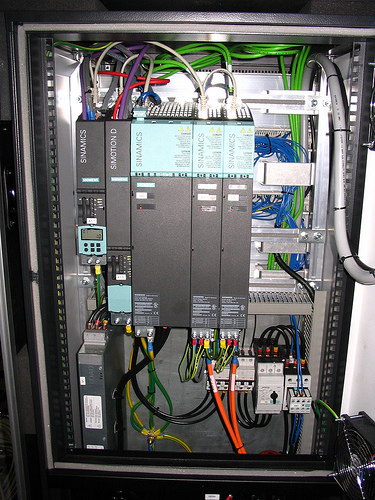

The motor control cabinet was next to be hoisted up but due to it’s physical size we knew it would be tricky. Sure enough the bulky box was really tough to maneuver through the hole and off the grid to the stage left grid level. We needed to temporarily replace the floor section we had removed to give us the floor space to get everyone round it and it moved into position.

The bags of cables, tools, brackets and a few other bits were hoisted up and the floor section was again replaced finally.

Next we moved the beams to a 5 meter square type arrangement for and placed a winch beside each beam since Charlie needed to fix some hardware clamps to the beams before the motors were placed in position.

With all the stuff now at grid level we called time out and headed home

Tuesday 1st April - Day 2

We arrived in at 9am and immediately went to the grid. The beams were now ready to have the winches lifted onto them and one by one the three of us lifted each winch carefully onto it’s respective beam. Bolts were tightened, alignments were checked carefully and power and encoder cables were connected.

The idea behind this system is that the beams can be placed anywhere on the grid as long as the supporting I-Beam spans the structural members. The winches can be placed on the beam and slid left or right giving the facility to drop a line “almost” anywhere on the stage. With 4 winches we can set up full stage width bars, 2 smaller bars, upstage / downstage bars, diagonal bars, individual points and many other combinations.

Charlie them began reeving up the winches with 25 meters of steel wire rope on each. Since our grid is only 15 meters this gives us ample flexibility should we want to divert lines down and along the floor, for instance, to pull trucks. The meticulous reeving of the winches took quite a while so Stephen and I busied ourselves between cable running duties with tidying the grid which has been neglected for years.

As each winch was reeved up with it’s wire rope Charlie explained how to set the “hard limits” of the winches which is the physical tripping of a user set micro switch designed to protect the winch itself at “Ultimate Limits” and the installation parameters “Initial Limits”. The only one’s were are likely to touch in the future are the initial limits.

With all four winches now powered up, reeved up and safety limits set we retired to the pub for a few light ales.

Wednesday 2nd April - Day 3

Vicky arrived this morning to join us and after some software updates for the Illusionist desk, which was sitting on top of the MCC in the grid, she set about installing the Chameleon software on the PC’s in room 2.47. Brian from IT joined us and helped with the complex install which took about 30mins per PC.

Charlie and Andrew ran various diagnostic tests on the system while Stephen and I helped as much as we could or continued with the huge task of tidying and ordering the dumping ground that the grid level has become.

After lunch we decided to move the MCC from it’s position on Stage Left grid level, right over to Stage Right. This will allow the Illusionist desk to be positionable any place on the flyfloor as required and also provide enough cable to set up the desk at stage level for classes.

The MCC, The desk and all the cables were unplugged and the whole system was re-routed over to stage right. This allowed Stephen and I to effectively cable up again from scratch which was great and tested our notes we had been taking over the past two days. The Illusionist was set up on the flyfloor just sitting on it’s own flight case and once everything was plugged back up , powered and checked we called it the end of the day.

Thursday 3rd - Day 4

Stephen sourced a table first thing and the desk was repositioned in a much better position than the flightcase from the day before.

Stephen and I, armed with notebooks, manuals and empty brains began our desk training

Vicky took us through the levels of training that Stage Technologies had defined and we each had a chance to get our hands on the desk. After lunch we moved our training to room 2.47 so that we could assess how it would be used by the students and to allow both Stephen and I to work simultaneously. The PC lab and the way that the PC’s have been set up by the Stage Tech install is an excellent facility and will allow students to play and experiment in a virtual environment without the worry and safety concerns of the real motors. Once comfortable with the virtual environment it will make the transition to the real desk and the real system less intimidating.

We left the PC lab and went back to the flyfloor to finish up some training that required the real winches and control. Finishing around 8:30 we were all tired and hungry and so food and beers (leading on to malt whisky) were sought and a great night of chat, ideas and future projects & collaborations ensued.

Friday 4th April - Day 5

With slightly fuzzy heads we continued our training, moving from basic operation to complex multi target moves and trigger functions. We had decided the previous evening to move two of the motors and reset initial hard limits as practice. The idea was that I would continue on the desk with Vicky while Stephen moved one winch with Andrew then we would switch. This worked out extremely well and I’m glad we did this as it will be the normal set up procedure when we come to set up the winches for performance.

In the afternoon we pushed the system to it’s limits forcing errors and trying to snag any remaining problems before Andrew and Vicky were due to leave.

5pm came very quickly and Andrew and Vicky officially handed over the system to us and with many hand shakes and thanks we said goodbye as they left for the airport.

I feel confident that we have a really good flexible system that will allow designers and technologists to push what is possible on our stage and the training I can now design for our students will place RSAMD as the forerunner for automation education.