War and Peace

The idea of reconstructing the original version of Prokofiev’s opera War and Peace resulted from the opportunities provided by Celtic-Cossack Connections: to collaborate in the performance of a work which neither of the two Conservatoires would be likely to tackle on their own, which needed the participation of native Russian singers, which would present a challenge, and which would make an international creative impact.

The opera has a long and tangled history: first conceived in the late 1930s, it was started in the months before the Second World War – which gave it contemporary relevance and political backing – and in its first form was completed in the spring of 1942. This initial version failed to find approval with the Soviet authorities, however, and the opera was subjected to continual revision in the eleven years until Prokofiev’s death in 1953. By this time it had grown to 13 scenes, lasting about four hours. It has been performed in many edited versions since then, but the original has remained amongst the composer’s manuscripts in Moscow.

No musical material has had to be invented for the reconstruction; the sections discarded in the revision process have been orchestrated, as far as possible in keeping with Prokofiev’s distinctive style. The outcome reveals a work much closer to the ideals of Tolstoy, with greater emphasis on the personal and intimate and less focus on the national and tableauesque.

The Opera was staged in January 2010 by a joint effort between the Royal Scottish Academy of Music and Drama (RSAMD) and Scottish Opera. A student team managed this production mentored and supervised by the staff of Scottish Opera.

Creative Team

Director - Irena Brown

Set & Costume Designer - Chloe Lamford

LX Designer - Joanna Town

Production Manager - Andrew Storer (RSAMD), Darren Joyce (Scottish Opera)

Stage Management Mentor -

Stage Manager - Emma Whoriskey

Deputy Stage Manager - Kieron Johnson

Assistant Stage Managers -

Electrics Mentor - Stevie Powells

Production Electricians - Puleng Mabuya, Michella Fee

LX Board Op. -

LX Crew -

Technical Stage Mentor - Ben Howell

Technical Stage Manager - Louise Marr

Technical Stage Crew - Martin Aitken, Scott Bremner

Scenic Elements

6 x Masking Pillars with Returns

Slider Wall

6 x Sliders

1.2m Steel Deck Platform

1.2m x 15m x 1.2m Trucked Steel Deck Section

Flown 1920's Projection Screen

8m Wooden Ramp

Flown Wooden Structure

Napoleons Tent

3 x 20 minute Snow Drop

Technical Solutions

6 x Masking Pillars with Returns

The four masking pillars DS consisted of a hard black masker with a grey textured 600mm return that fitted onto the edge of the black masker and was secured with four back flap hinges. These had to be moved to the side during each reset so the LX team could fill their DS snow machines.

The two US maskers were textured flats with a hinged return that were flown and secured to the US edge of the 1.2m steel deck platform. These not only acted as masking flats but were a very useful storage space for the 100 sand bags used in the second half.

Slider Wall

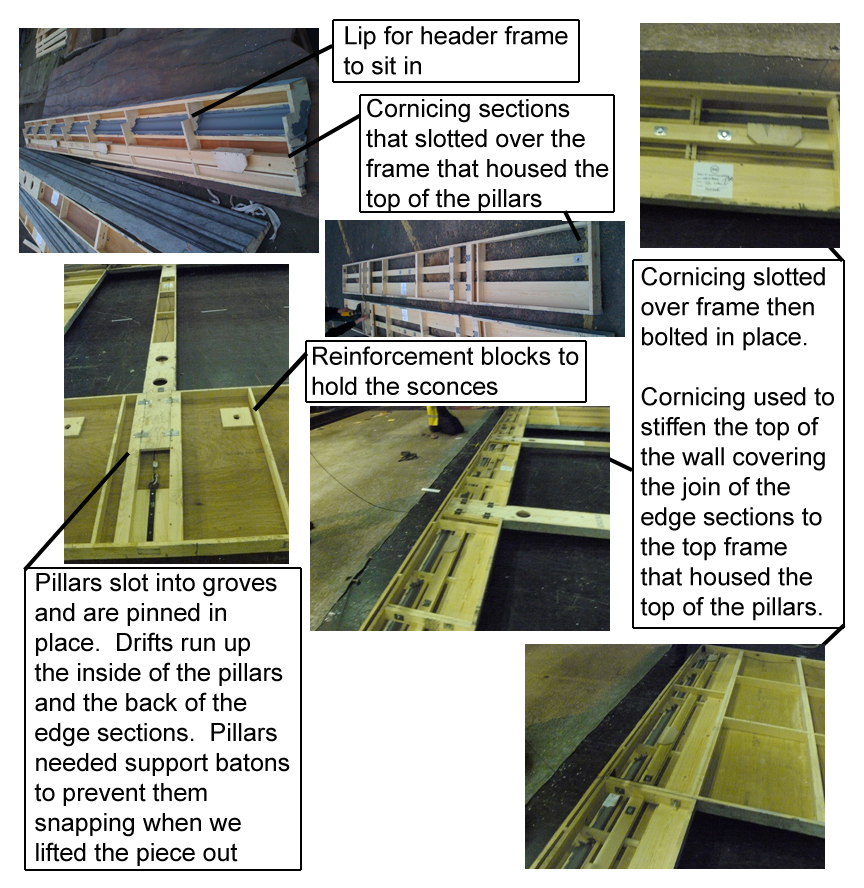

This was the most major scenic piece it divided the stage in half across stage and marked the change in level of stage - behind the wall was a 1.2m high steel deck platform. This wall contained 6 door way sections that were filled by 6 sliding doors that each moved independently. The wall consisted of a solid lower 1.2m high section 5 x 250mm pillars and two side panels. It was then topped by cornicing and a canvas header stretched over a frame to continue the impression of solid wall. Even with the framed header flown separately the wall weighed 561kg and had to be flown over two counter weight fly bars.

6 x Sliders

These were the most technically challenging part of War & Peace: they formed the scene changes through the first half of the opera and were required to move independently to a variety of positions. They had to be controlled from the wings, move in time with the music, and at points mirror each other in their movements.

In order to achieve this the 6 sliders were mounted on two tracks of EEE tab track and two stipulations were made: one, that the 3 SL sliders could not cross Centre Line to SR and similarly the 3 SR sliders could not cross Centre Line to SL, and two, the outer two sliders were controlled manually i.e. not by ropes (as the inner four were), and could therefore only fill the outer two door ways.

Due to the tight scheduling for fit ups in Theatre Royal and Edinburgh Festival Theatre and the huge amount of time required and the complicity of building and running the rope lines of the tab track I decided to keep the tab track built and the rope lines in the track and transport the tab track as one unit split in the middle and folded together. The first time we attempted this manoeuvre we realised very quickly that we would have to leave a large amount of slack in the lines to allow the tab track to be folded back on its self. The scenery carrier tops remained on the tab track and the sliders fitted with the scenery carrier bottoms were removed and transported separately.

All together the tab track and sliders weighed 621kg it was decided to hang the tab track on box truss suspended by 2 x 1ton motors mounted in the grid, motor down. Due to this approach it took quite a while to level the truss and being chain motors there was a limited degree of accuracy in their movement.

The sliders were fitted with spades made of 6mm ply wood with curved bottoms that fitted into two guide tracks in the 18mm floor of the 1.2m steel deck platform. Due to the unevenness of the stage floor and the steel deck these guide tracks undulated across stage. This meant that the slider spades would ground out at one point and float above the guide track at other points, finding the sweet spot where this didn't happen proved to take quite some time and was then effected by the number of opera singers that were stood on the platform at any one time or point. The decision was made to deepen the track from 18mm to 25mm this gave enough room for manoeuvrability and enough of a buffer to absorb the variance in stage floor level and movement of the 18mm floor.

As the sliders were used the wood of the guide track and the wood of the spades began to rub and squeak loudly, simply rubbing candle wax over the surface of the spades regularly was enough to prevented this.

1.2m x 15m x 1.2m Trucked Steel Deck Section

A 1.2m steel deck platform streching the full 15m width of the stage and This platform stretched the full width of the stage with two sets of get off treads at either side

Flown 1920's Projection Screen

8m Wooden Ramp

Flown Wooden Structure

Napoleons Tent