The Wonderful World of Dissocia 2023

Overview

Technical Stage Department

"The Wonderful World of Dissocia" contained several challenges for TSD. The act 1 set consisted of a patchwork of carpets,a walkup trap and a 6000x4860mm flat that needed to fall at the end of the act. The act 2 set consisted of 3 steel deck trucks and a roof piece which came together to create the psych ward, this was then completely boxed in with black masking.

Falling Wall

At the end of act 1 the designer requested that the large sky flat at the back would fall leaving behind only a door that an actor would then step through.To do this we used a rather simple approach relying mostly on pin hinges. The falling wall was made of 3 separate flats meaning care had to be taken to avoid the flat flexing and being damaged as it fell.To do this we installed two strengthening battons on the back of the falling wall, one near the top and one near the top of the door section.We then attatched 4 french braces to the back of the flat, these where what held up the flat during the show until it was time for them to fall.These braces came from the RCS stock and are usually used for hard masking. The wall was then walked up by a team of 7 and moved into position. 4 opera pin hinges where then screwed into the bottom edge of the front face of the flat and then into the floor, these where to keep the wall from moving forward as it fell.Another 4 opera pin hinges where then screwed into the french braces and the floor, these held the wall upright until it was time for the fall.

To operate the fall two crew members would enter from a gap in the void to behind the wall, on stage managements cue they would remove the pins on the hinges connecting the french braces to the floor, they would then stand on the braces until they were given the "Go". On the "Go" they would step off the braces,give a coordinated push on the back side of the flat to start the fall and run back into the void to avoid being seen by the audience. With this method once the wall starts falling there is no way of stopping it. For this reason there was a safety zone planned with an extra 1m buffer to keep the performer who was standing at the front of the stage safe.The stage manager would not give clearance for the pins to be pulled prior to the performer moving into this zone.

To reset the wall,7 crew members were required.4 were needed to walk the wall back up,with 2 pulling on the braces for assistance and at the ready to put the pins back in. The additional member was the stage supervisor who would call the lift and give assistance on the braces.

Lighting

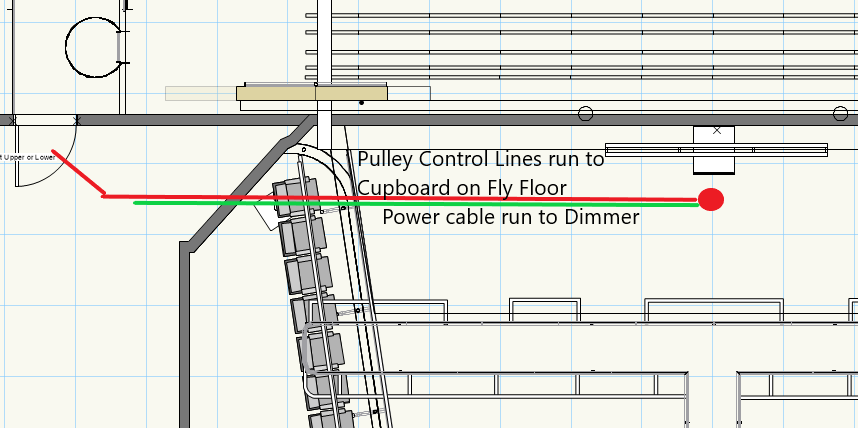

Lighting for the Wonderful World of Dissocia had several unique challenges on this version of the production. The first to look at is the flying pendant light fixture which had to be installed on the auditorium side of the proscenium arch. To achieve this, a system of pulleys and wire rope fairleads was used to allow both the control line for the pendant, and the power cable to move, and lower in/raise out the pendant.

The Basic idea would be to utilise a hanging pendant light and have this rise and fall:

However it would need controlled via a rope from somewhere off stage:

With this in mind a system would need to be installed within the Athenaeum gods to accommodate the rigging, and ensure that the control line for raising and lowering could be run into the ONSTAGE side of the proscenium or to somewhere it could be operated without needing a person in the Gods. To do this, the control line was routed into the cupboard just off the entrance into the Fly Floor.

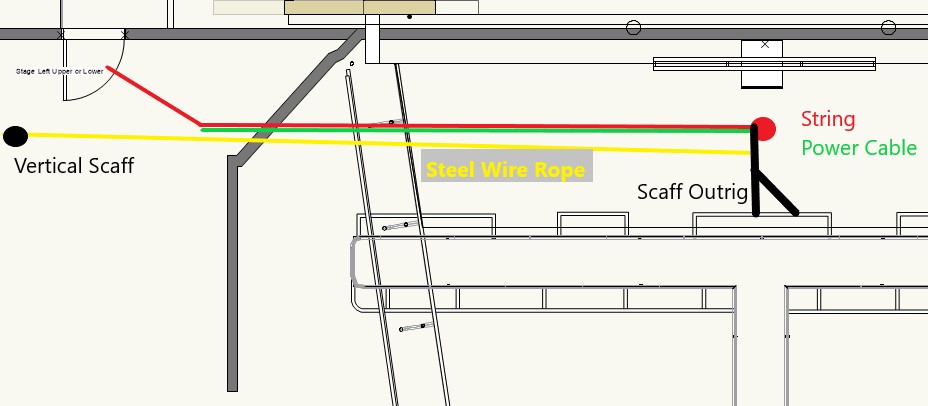

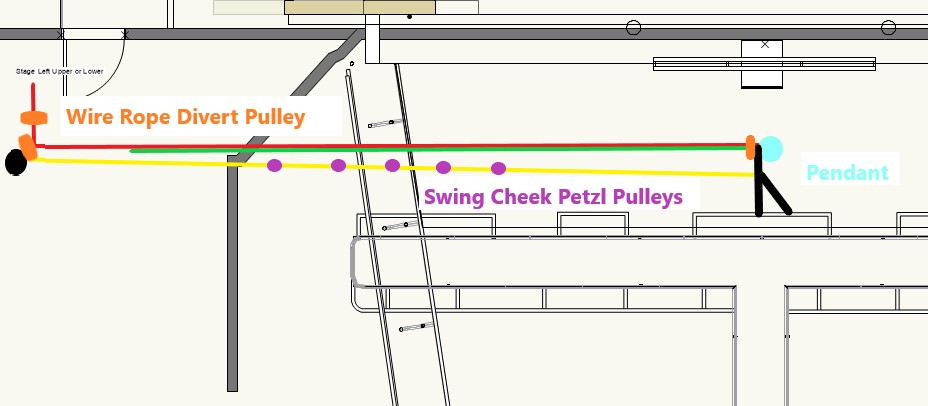

The rigging would be relatively conventional and just need to have a support arm in scaff from the catwalks, as well as an upright scaff to support a tension line:

To ensure that the cable powering the pendant could be flown in and out smoothly, along with the physical pendant, the cable was was supported by swing cheek pulleys which ran along a tensioned steel wire rope:

The final installation allowed the pendant to easily fly out as part of a cue, and then be lowered in for the Act 1 reset. The physical rigging looked like this:

-

Tension Line

-

Pulleys

-

Upright Pole - Note the wire rope fairlead diverting the control line

-

Top view - Note wire rope fairlead

Another prop/set item the LX dept work on was the wireless battery powered Hurricane Lamp. This lamp was simply adapted to have am SES/E14 bulb holder mounted inside. Via and installed switch a 9v battery was wire to the lamp holder. A nicely shaped T25 lamp with LED filaments that runs at 12v was bought from Amazon via a supplier called Bonlux.

The end result looked like this:

The lantern require a little modification to widen a hole for the lamp holder to fit. This was done by widening the wick holder. The lamp holder was mounted on some M10 threaded rod which is hollow (a common part in Chandelier making). With washers and locking nuts, the lamp holder was mounted to sit in place in the centre of the lantern. Two wires were simply soldered onto the switch for operation and a "battery clasp" for a 9v battery was added to give power - polarity is simply Red to Brown and onto the switch, and black to blue wire straight to the lamp holder. As the bulb was actually very bright, a piece of Lee 1.2 Stop Neutral Density was wrapped around the bulb to dim it slightly. The power supply used on this show was a 9v Lithium Ion battery which was USB-C rechargeable.

-

Complete lantern - Bunjee cord with hook for securing Base and red/brow blue/black wiring polarity

-

SES\E14 lamp holder and Switch

-

Lamp holder with M10 hollow threaded rod

-

Lamp holder from inside base and switch

-

9v Lithium Ion USB-C rechargeable battery

The lighting design for show show was delivered by Kai Fischer and drawn in AutoCAD. As AutoCAD operates differently and doesn't contain symbol data within the DWG export, the PLX had to import the DWG file into Vectorworks and redraw the lighting symbols into the VWX file to allow for file referencing with other depts. By utilising the Vectorworks "Data Visualisation Tool", the LD's plan could be highlighted in RED, and then the VWX symbols laid on top in standard BLACK. This meant that wherever the LD had a symbol drawn, the PLX could be sure of having put the correct VWX symbol in the same place. Any RED symbol, without a VWX symbol on top, meant a fixture had been missed in transcribing the plan! This also worked whenever the LD updated his plan and moved/changed fixtures.

-

Booklet of Overhead Plans (Dimmers, Socapex, DMX, 16A etc)

-

SES\E14 lamp holder and Switch

-

Lamp holder with M10 hollow threaded rod

-

Lamp holder from inside base and switch

-

9v Lithium Ion USB-C rechargeable battery