A Midsummer Nights Dream 2013 - opera: Difference between revisions

Ffindlater (talk | contribs) |

|||

| Line 179: | Line 179: | ||

='''Electrics'''= | ='''Electrics'''= | ||

CHIEF PLX - JAMES GOW | |||

DEPT PLX - BEN TERRY | |||

OP CHARGEHAND - ADAM MCCALL | |||

AV OP - ROY HERD | |||

LX OP - NEIL FOULIS | |||

[[File:DSCF0989.JPG]] | |||

As you can see the revival of this show is fairly large for electrics. | |||

Detail was key during the rig. | |||

Safety and percision was key during the rig of the Neon signs and Flurry tubes. | |||

[[File:NEON.png]] | |||

How I organised the FTs. | |||

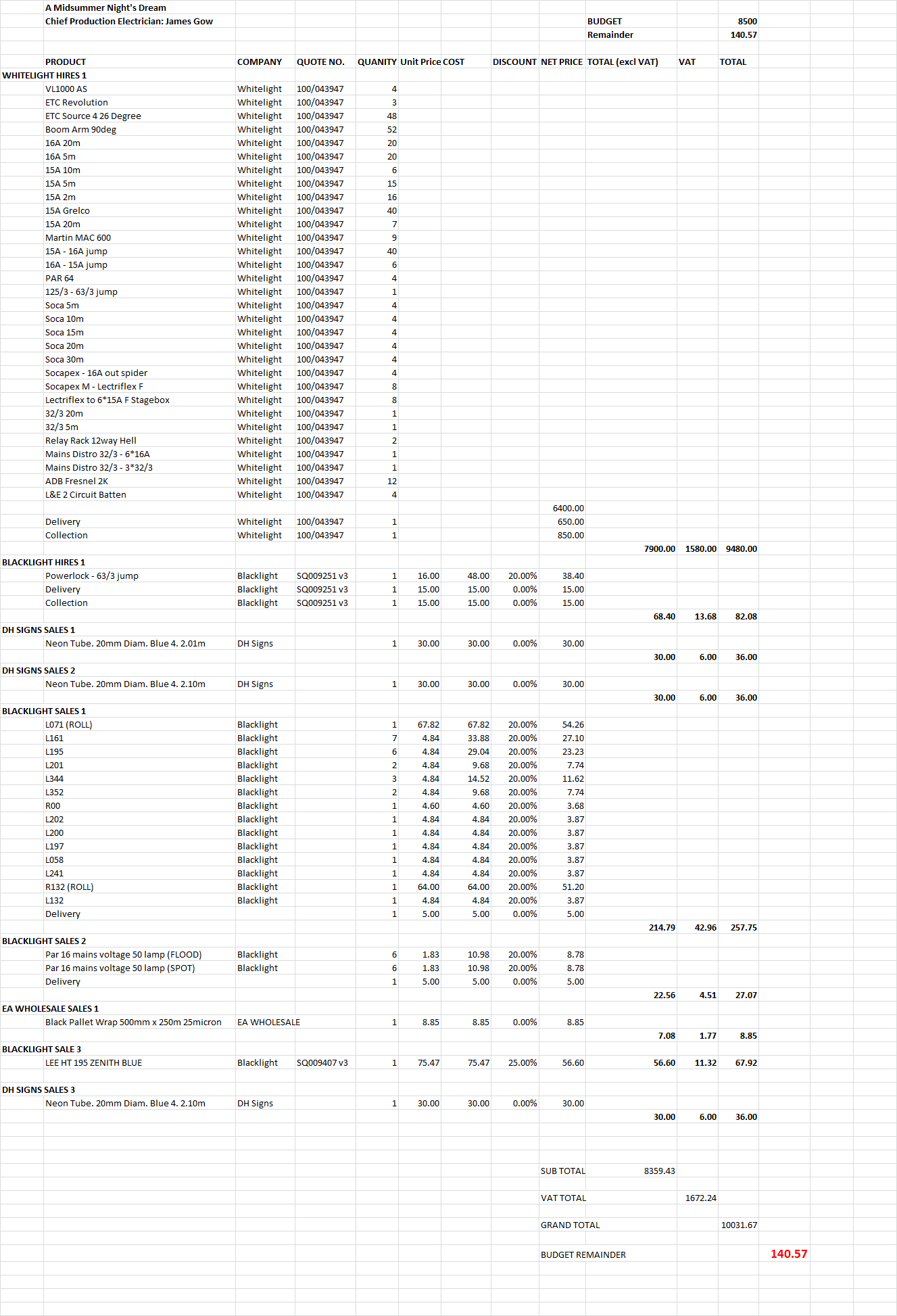

[[File:BUDGET.png]] | |||

To give you an idea of costs and the scale of hired equip. | |||

Revision as of 01:37, 6 February 2013

| A Midsummer Nights Dream 2013 - opera | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||||||

A Midsummer Nights Dream

| ||||||||||||||||||||

Story

Now in its eighth year, our ambitious Winter collaboration with Scottish Opera continues with a celebration of the 100th anniversary of Benjamin Britten’s birth with a revival of Olivia Fuchs’ 2005 production for the Royal Opera House of A Midsummer Night’s Dream. Adapted from the Shakespeare play in collaboration with Peter Pears, Britten’s version is centred on the ethereal world of the fairies rather than the human action at the heart of the original.

Crew

- Production Manager-

- Stage Manager- Fiona Findlater

- Deputy Stage Manager-

- Assistant Stage Managers- Rosie Barber, Ashley Kerray

- Technical Stage Manager- John Beggan

- Deputy Technical Stage Manager/Flys- Jennifer Howes

- Deputy Technical Stage Manager/Automation - Andrew McCabe

- Assistant Technical Stage Managers -

- Chief Production Electrician- James Gow

- Deputy Production Electrician-

- Production Electricians-

- Lighting Programmer/Operator-

TSM

Pucks Rope

SAFE SYSTEMS OF WORK 5

TASK – Artist Rope into Position

HAZARDS – Rope, Stinger dropped from Height Rope to come loose during performance

EQUIPMENT REQUIRED – Fixed Truss Piece in grid 2 Wire Rope Stinger from grid Master link tied between 2 fly bars to stop swing Ratchet straps to tie off flybars

PROTECTIVE CLOTHING –Safety Shoes, Hard Hat

PROCEDURE-

1. Wire rope Stingers taken to grid 2. Fixed onto load tested position 3. Lowered in to plump position 4. Artist rope taken up on to grid shackled on to stingers 5. Master link attached to fly bars 6. Rope dropped in from grid and through master link 7. Flybars ratchet off to flyfloor 8. Rope Tried and tested

Chinese Pole

SAFE SYSTEMS OF WORK

TASK – Aerial Artist Pole Installation

HAZARDS – Pole/equipment falling from height

EQUIPMENT REQUIRED – Bracket arm required to secure in auditorium box position Boom plate/tank trap Scaff clamps Fixings for boom plate to deck

PROTECTIVE CLOTHING –Safety Shoes, Hard Hat

PROCEDURE 4 crew required 1.Bottom pole walked up with 2 crew with line on through pulley on scaff bar in auditorium box crew in box taking strain on rope line 2. Pole put into through deck hole and into boom plate and fixed into position 3.1 crew member in each box in auditorium as top Pole part is lifted up 4. Rope line dropped in from crew member in top box 5.Rope clove hitched and scaffolders knot onto Top pole 6. Guided up by grounds men as crew in boxes pull up with rope 7. Guided into positioned and top pole slotted into bottom pole

Automation

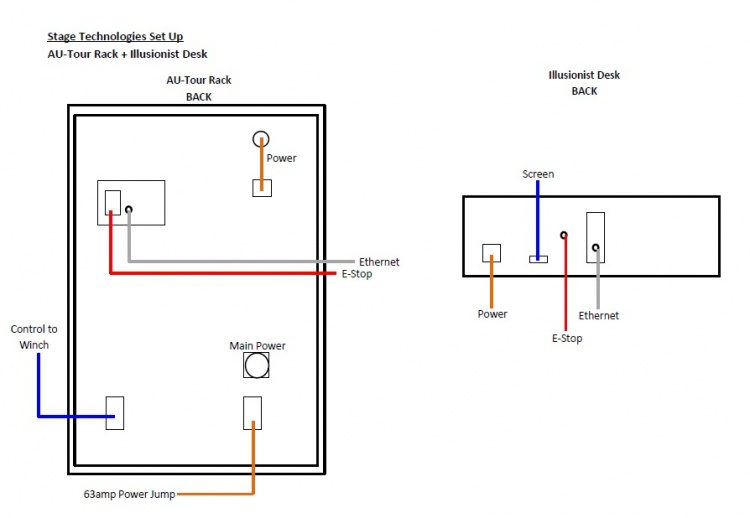

As part of the set up for A Midsummer Nights Dream a performer had to fly in what was called the 'bower box'. To achieve this effect we used a Stage Tech system similar to the one we use in the New Athenaeum Theatre. The system had been changed slightly and added to in order to fly a performer and to achieve the correct effect.

The system was made up of the following equipment;

- Illusonist Control Desk

- Au-Tour Rack

- UPS

- Big Tow Winch (modified with 2 points)

- Truss

- Various Drifts

- Swifter Lines (tention lines)

Because the winch only had 2 points coming from it, we attached them to truss and then attached the 4 bower points to the truss so that; A-all of the points coming off the bower were straight and B-We could lift the bower using the 2 lines on the winch and did not have to have an even more complicated system

Below is a diagram of how the system looked and how it was cabled up.

Stage Management

Scene Settings

Some of the scenic elements of this opera moved around very freely, and very often, particularly the blue velvet Dream Chair. We kept track of this by having a thorough scene setting list. Below are a few examples.

Creating the bursting paper effect

We used professional photography background paper and attached it to the Cage Truck using wide industrial strength double sided sticky tape. Before applying the double sided tape, we attached a layer of Gaffer Tape to the perspex of the Cage Truck so that the sticky residue from the double sided tape did not remain when the paper had to be quickly struck during an interval.

The roll of paper we bought was 2.72x25m. The colour, ChromaBlue_91*. The manufacturer, 'Colorama.'

We bought the paper from a company in Manchester who were very helpful and had the paper sent up to us within 24 hours. The company was Professional Film Direct. Their phone number 0161 273 3003. Their website www.pfdstore.com

King's Theatre Edinburgh

When touring to the King's we came up against a MAJOR problem. The main set elements are on wheels, and the stage is raked!!! The rake at the King's is 1:24, so not too severe, but severe enough that we had chairs and shelf trucks sliding close to the orchestra pit.

In order to adapt the set for a raked stage, we had heavy duty brakes attached to the back of the Shelf Truck, and also had a line running off the back of the truck and into the wing, so that a member of TSM could hold on while action was taking place on top of the truck. The Cage Truck had a pivot point that was screwed into the floor. The Red Theatre Chairs all had small brakes added to the back, but these weren't used all the time. At the top of the show we set the chairs so that the casters we horizontal to the front of the stage so they wouldn't roll down the rake. Although this is a simple solution, the brakes were much more reliable and successful to use. When the chairs were set without brakes it only took a small nudge to set them off.

So that the cast could get used to the raked stage we held a special rehearsal session in which we ran through any movements that were affected by the rake or adapted set elements. We held a specific fight call each evening so that the Lovers could get used to the rake.

This was all thoroughly risk assessed

Electrics

CHIEF PLX - JAMES GOW DEPT PLX - BEN TERRY OP CHARGEHAND - ADAM MCCALL AV OP - ROY HERD LX OP - NEIL FOULIS