Project Trucks: Difference between revisions

No edit summary |

|||

| Line 3: | Line 3: | ||

The brief we set ourselves was to use the automation system to move two trucks across the stage, whilst flying objects onto them from above. We thought this would be easy enough that we could achieve it in two days, yet tricky enough to set us a reasonable challenge. | The brief we set ourselves was to use the automation system to move two trucks across the stage, whilst flying objects onto them from above. We thought this would be easy enough that we could achieve it in two days, yet tricky enough to set us a reasonable challenge. | ||

== Design == | == Design == | ||

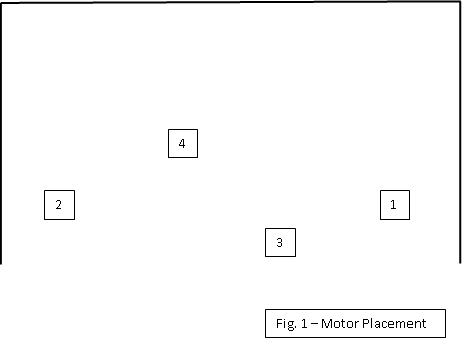

The four motors were already in positions (see Fig.1) and due to time restraints we decided to leave them as they were. By using the swivel pulleys already in place on motors 1 & 2 and using floor mounted tilting pulleys we were able to re-route the lines from the motors to get two lines of travel (see Fig.2&3) | |||

[[Image:Projtrux1.png]] | |||

[[Image:Projtrux2.png]] | |||

[[Image:Projtrux3.png]] | |||

== Construction == | == Construction == | ||

== Programming == | == Programming == | ||

== Outcome == | == Outcome == | ||

Revision as of 21:34, 3 May 2010

Project Trucks was a small challenge we set ourselves after first learning to use the automation system in the Atheniaum Theatre. The system is Made by Stage Technologies and is made up of; the Illusionist control desk running the EChameleon software, the AU:TOUR portable 4-way control rack, and four BigTow winches and point hoists.

Brief

The brief we set ourselves was to use the automation system to move two trucks across the stage, whilst flying objects onto them from above. We thought this would be easy enough that we could achieve it in two days, yet tricky enough to set us a reasonable challenge.

Design

The four motors were already in positions (see Fig.1) and due to time restraints we decided to leave them as they were. By using the swivel pulleys already in place on motors 1 & 2 and using floor mounted tilting pulleys we were able to re-route the lines from the motors to get two lines of travel (see Fig.2&3)