The Seagull: Difference between revisions

SMacluskie (talk | contribs) |

SMacluskie (talk | contribs) |

||

| Line 79: | Line 79: | ||

Production Electrician [[Michaella Fee]] | Production Electrician [[Michaella Fee]] | ||

Electrics Crew [[Emily Lennox]] , [[Lauren McKay]] , [[Madeleine | Electrics Crew [[Emily Lennox]] , [[Lauren McKay]] , [[Madeleine Hillmann]] | ||

==Technical Challenges== | ==Technical Challenges== | ||

Revision as of 16:00, 9 December 2009

By Anton Chekhov

A version by Stuart Paterson from a translation by George Calderon

Directed by Hugh Hodgart and John Kazek

Designed by Richard Evans

Music Composed by Anna Shucksmith

"Valse Melancolique" composed by Edvard Grieg

2 - 7 November 2009 / 7.30pm / New Athenaeum Theatre

The action takes place on Sorin’s estate.

Two years pass between Act Three and Act Four.

The translation by George Calderon was performed by the Scottish Repertory Company in Glasgow, November 1909, and was the first ever production in English of ‘The Seagull’.

Flickr set by Christine Murphy

Cast

Arkadina, an actress Olivia Knowles

Konstantin, her son Pierce Reid

Sorin, her brother Leon Vickers

Nina, young daughter of a rich landowner Jessica Bile

Shamrayev, retired army lieutenant, manager of Sorin’s estate Rhys Wadley

Polina, his wife Sharita Scott

Masha, their daughter Helen Darbyshire

Trigorin, a writer Cathal Finnerty

Dorn, a doctor Adam McNamara

Medvedenko, a schoolteacher Gary French

Yakov, an estate worker Martin McBride*

Cook Natalie Songer*

Maid Molly Vevers*

First year BA Acting students

Production Team

Stage Manager Vicky Adamczyk

Deputy Stage Manager Anne Hamilton

Assistant Stage Managers Laura Jarvis, James Clelland

Technical Stage Manager Kirsty Campbell

Production Technicians Thomas Velluet - Draper , Scott Bremner , Martin Aitken

Production Electrician Michaella Fee

Electrics Crew Emily Lennox , Lauren McKay , Madeleine Hillmann

Technical Challenges

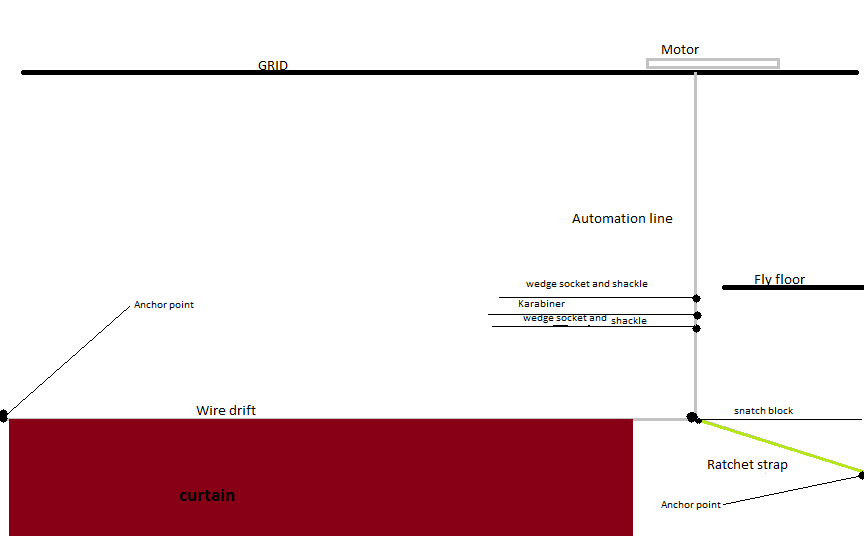

During the recent production of "The Seagull" there were several technical challenges that we had to overcome. As well as designing and constructing a 6 piece Kabuki drop, we also had to come up with a way of rigging quick release tension wire system. Initial attempts at constructing this included using a Tirfor which as expected turned out to be far too loud to de-rig during a short scene change. After much deliberation, it was decided that the most effective method involved using an automation motor to create the desired effect.

Having moved a motor to the desired position, we then lowered the line to meet a 15metre wire drift and attached the two with wedge sockets and shackles. we also added a karabiner between the two lines in order to make the release time quicker and simpler. At a lower point in the line (the same height as the top of the curtain a snatch block was used to divert the direction of the line. A ratchet strap was attached to the snatch block and anchored to a scaff bar at a 45 degree angle which would maintain the horizontal position of the line.

Trellis pieces

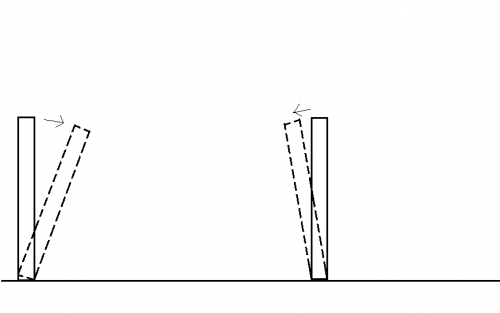

Another effect that we had to achieve involved safely tilting 6 large trellis pieces both on and off stage. This was required to be a live move which was cued and specifically timed. Throughout the production period there were a few solutions that were considered. Each trellis piece was over 6 meters tall and 300 mm wide. The trellis was made from box steel and although it was lightweight it was also extremely flexible, this also affected the way we could hang and handle the pieces.

We started by hanging the trellis from the top of the structure. Having found an effective way to attach the hardware we initially decided to to hang the pieces vertically on spot lines.This next picture shows how we attached the hardware. First we measured down 300 mm from the top of the trellis and drilled a hole through the box steel front to back. As a bolt was passed through the hole it was also passed through a 1 meter sling. To the other end of the sling we attached our shackle and drift to which we tied on our hemp lines. Two vertical lines were required for each trellis piece.

Although this method kept the pieces vertically straight it allowed for very little horizontal movement which was critical for the tilting effect. To remedy this we added two horizontal lines to each trellis which were cleated off on each fly floor. This method provided sufficient horizontal force to tilt the pieces and hold them in place.

This picture shows how the horizontal hemp lines were attached to the trellis pieces and how the lines tightened/expanded to tilt the trellis.