The Seagull: Difference between revisions

SMacluskie (talk | contribs) No edit summary |

No edit summary |

||

| Line 8: | Line 8: | ||

[[Image:tension wire picture.png]] | [[Image:tension wire picture.png]] | ||

==Trellis pieces== | |||

Another effect that we had to achieve involved safely tilting 6 large trellis pieces both on and off stage. This was required to be a live move which was cued and specifically timed. Throughout the production period there were a few solutions that were considered. Each trellis piece was over 6 meters tall and 300 mm wide. The trellis was made from box steel and although it was lightweight it was also extremely flexible, this also affected the way we could hang and handle the pieces. | |||

Revision as of 21:18, 22 November 2009

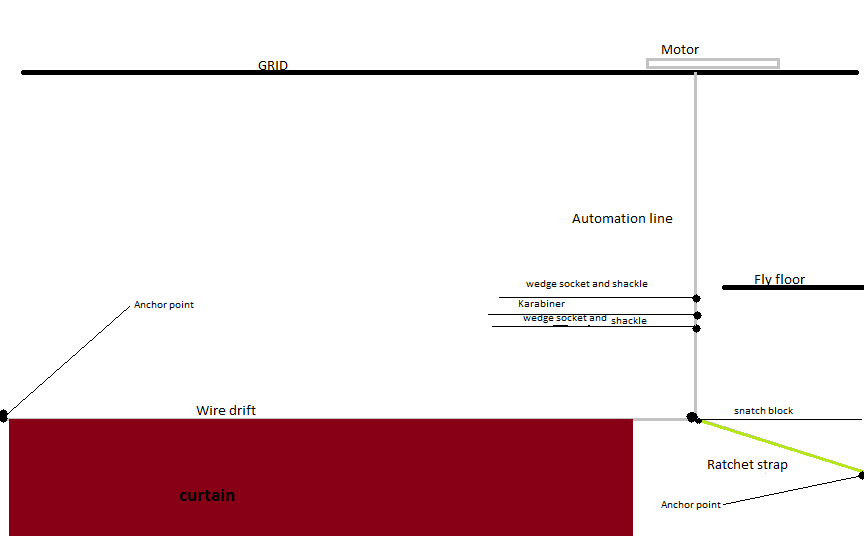

During the recent production of "The Seagull" there were several technical challenges that we had to overcome. As well as designing and constructing a 6 piece Kabuki drop, we also had to come up with a way of rigging quick release tension wire system. Initial attempts at constructing this included using a Tirfor which as expected turned out to be far too loud to de-rig during a short scene change. After much deliberation, it was decided that the most effective method involved using an automation motor to create the desired effect.

Having moved a motor to the desired position, we then lowered the line to meet a 15metre wire drift and attached the two with wedge sockets and shackles. we also added a karabiner between the two lines in order to make the release time quicker and simpler. At a lower point in the line (the same height as the top of the curtain a snatch block was used to divert the direction of the line. A ratchet strap was attached to the snatch block and anchored to a scaff bar at a 45 degree angle which would maintain the horizontal position of the line.

Trellis pieces

Another effect that we had to achieve involved safely tilting 6 large trellis pieces both on and off stage. This was required to be a live move which was cued and specifically timed. Throughout the production period there were a few solutions that were considered. Each trellis piece was over 6 meters tall and 300 mm wide. The trellis was made from box steel and although it was lightweight it was also extremely flexible, this also affected the way we could hang and handle the pieces.