Sweet Charity: Difference between revisions

No edit summary |

|||

| Line 85: | Line 85: | ||

[[File:Slider Concept Auto Lines 1.jpeg|300px]] | [[File:Slider Concept Auto Lines 1.jpeg|300px]] | ||

===Counterweight Cradles=== | |||

After some more brainstorming I decided than rather doing a double purchase CW system on the other side of the automation. That I would go with a 1:1 meaning the weights had to have 12m of movement. Because the weights were traveling so far I wanted a way to guide them, so they don't build up wobble etc. Therefore, I built some CW cradles and rated them, which can then be a product for future use as it holds the in house fly weights. | After some more brainstorming I decided than rather doing a double purchase CW system on the other side of the automation. That I would go with a 1:1 meaning the weights had to have 12m of movement. Because the weights were traveling so far I wanted a way to guide them, so they don't build up wobble etc. Therefore, I built some CW cradles and rated them, which can then be a product for future use as it holds the in house fly weights. | ||

| Line 98: | Line 99: | ||

[[File:Final Cradle.JPG|600px]] | [[File:Final Cradle.JPG|600px]] | ||

[[File:|300px]] | ===Track, Truss and Pulleys=== | ||

To reave all this system together required a lot of SWR and many pulleys, we managed to borrow a lot of pulleys from NTS. However, again lots of metal work required to get them mountable the way we needed. | |||

The automation used its normal beams and header pulleys on the grid. Which then went down into some divert pulleys along the truss. | |||

The CW side of the system went through pulleys on the truss up to the grid, through another pulley along the grid. Then down again where it attached to the cradle. These two diverts on the grid used 1m sticks of truss to span the gap. The cradle pulleys also had custom made brackets to rig the catenary wires from, which guide the cradles down. These were then tensioned at floor level using turn buckles. | |||

[[File:Concept Testing.jpeg|300px]] [[File:Concept Testing 2.jpeg|300px]] | |||

[[File:NTS Borrowed Pulleys.jpeg|300px]] [[File:Scenery Carriers.jpeg|300px]] | |||

[[File:Grid Photo 1.jpeg|300px]] [[File:Grid Photo 2.jpeg|300px]] | |||

[[File:Slider Pulley Grid Truss.jpeg|300px]] [[File:Grid Photo 5.jpeg|300px]] | |||

[[File:Big Tow Sweet Charity.jpeg|600px]] | |||

==Deck Track (Ballet Barres)== | ==Deck Track (Ballet Barres)== | ||

Revision as of 20:52, 19 June 2024

.

| Sweet Charity | |

|---|---|

| Summary | |

| Dates 17th - 22nd June 2024

| |

| Location New Athenaeum

| |

| Creative Team | |

| Lighting Designer | |

| Sound Designer | |

| Production Team | |

| Head of Stage | |

| Head of Flys | |

| Deputy Stage Supervisor | |

| Production Carpenter | |

| Stage Manager | |

| Deputy Stage Manager | |

| Assistant Stage Manager | |

| LX Programmer | |

| Associate Lighting Designer | |

| PLX | |

| Production Sound Engineer | |

| Sound No.1 | |

| Technical Stage Technicians | |

| LX Technicians | |

| Sound Technicians | |

Overview

"Sweet Charity" is a classic Broadway musical that tells the story of Charity Hope Valentine, a dance hall hostess with a heart of gold, who dreams of finding true love and escaping her dreary life in New York City. Despite facing constant disappointments in her romantic relationships, Charity remains optimistic and resilient, always hopeful for a better future. Along the way, she encounters a colorful cast of characters, including her fellow dancers, eccentric suitors, and quirky acquaintances. Filled with lively dance numbers, memorable songs, and humorous moments, "Sweet Charity" is a tale of love, perseverance, and the pursuit of happiness in the bustling cityscape of the 1960s.

Technical Stage Department

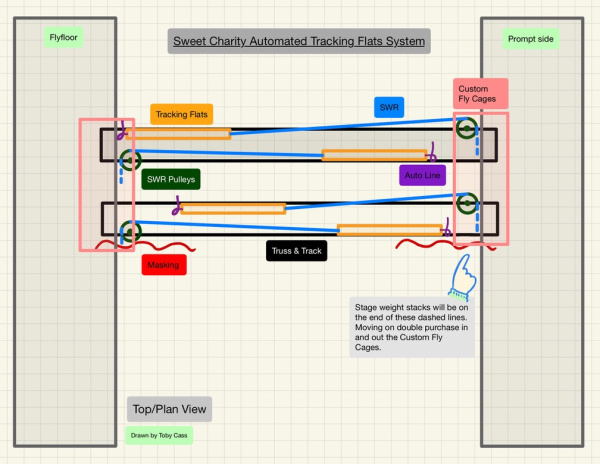

This show had to be very sharp and clean and minimal crew on stage. This in tern lead to some very technical systems which we therefore used in this production. The sliders which made up every scene were automated using the BigTow winches and the Epic desk. The Ballet Barres were in their own onstage track using a truck winch, to mirror the movement for symmetry. The Tower was on Kinesys to provide a hidden reveal behind the sliders.

Automated Sliders

The entire show depended on 4 sliders that move across the stage, creating different shapes and movements to frame each scene. I very early on decided for accuracy and repeatability this needed to be automated. But also for "neatness" as if it was on rope we would never coordinate 4 operators perfectly every time.

Concept Drawings for Slider System

Below are the original concept drawings and brainstorming ideas I had whilst coming up with the system. It turned out not too dissimilar to these but not exactly the same.

Counterweight Cradles

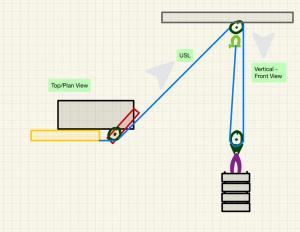

After some more brainstorming I decided than rather doing a double purchase CW system on the other side of the automation. That I would go with a 1:1 meaning the weights had to have 12m of movement. Because the weights were traveling so far I wanted a way to guide them, so they don't build up wobble etc. Therefore, I built some CW cradles and rated them, which can then be a product for future use as it holds the in house fly weights.

Below are some images of my build process and then how they looked rigged in the system:

Track, Truss and Pulleys

To reave all this system together required a lot of SWR and many pulleys, we managed to borrow a lot of pulleys from NTS. However, again lots of metal work required to get them mountable the way we needed.

The automation used its normal beams and header pulleys on the grid. Which then went down into some divert pulleys along the truss.

The CW side of the system went through pulleys on the truss up to the grid, through another pulley along the grid. Then down again where it attached to the cradle. These two diverts on the grid used 1m sticks of truss to span the gap. The cradle pulleys also had custom made brackets to rig the catenary wires from, which guide the cradles down. These were then tensioned at floor level using turn buckles.