Into The Woods 2023: Difference between revisions

| Line 104: | Line 104: | ||

This show had a very 'climbable' set, almost everything was made or reinforced for acting on, from the large 4m platform USR to the tiny tin bins with stage weights and reinforced lids. This meant access to all these high areas had to be thought of and built into the offstage wing planning. At first when all the set was delivered to the stage most platforms were accessed via ladders, however once the large platform was in place the SM team decided some of the cast would find going up a ladder so high quite difficult under time pressure etc. Therefore we devised a large staircase method which you can see below. | This show had a very 'climbable' set, almost everything was made or reinforced for acting on, from the large 4m platform USR to the tiny tin bins with stage weights and reinforced lids. This meant access to all these high areas had to be thought of and built into the offstage wing planning. At first when all the set was delivered to the stage most platforms were accessed via ladders, however once the large platform was in place the SM team decided some of the cast would find going up a ladder so high quite difficult under time pressure etc. Therefore we devised a large staircase method which you can see below. | ||

[[File:ITW - USR Staircase.JPG| | [[File:ITW - USR Staircase.JPG|300px]] [[File:ITW - Rolling GetOff Platform.JPG|300px]] | ||

The second image above is of the 'rolling get off platform' this is a truck that is never seen by the audience but rolls around the SR wing meeting the bedroom truck in whichever position it is in to provide access on and off the step which can been seen on stage. The angle of the bedroom truck also changed a lot so the rolling platform has a drawbridge that can be lowered to cover the gap created when the two don't meet flush. | The second image above is of the 'rolling get off platform' this is a truck that is never seen by the audience but rolls around the SR wing meeting the bedroom truck in whichever position it is in to provide access on and off the step which can been seen on stage. The angle of the bedroom truck also changed a lot so the rolling platform has a drawbridge that can be lowered to cover the gap created when the two don't meet flush. | ||

===Ground Plans=== | ===Ground Plans=== | ||

Revision as of 15:53, 3 December 2023

.

| Into The Woods 2023 | |

|---|---|

| Summary | |

| Dates 4th - 9th December 2023

| |

| Location New Athenaeum

| |

| Creative Team | |

| Director | |

| Designer | |

| Lighting Designer | |

| Sound Designer | |

| Video Designer | |

| Production Team | |

| Stage Supervisor | |

| Deputy Stage Supervisor | |

| Stage Manager | |

| Deputy Stage Manager | |

| Assistant Stage Manager | |

| LX Programmer | |

| PLX | |

| Technical Stage Technicians | |

| Sound 2 | |

| PSE | |

Overview

Technical Stage Department

Iris Effect

Moon

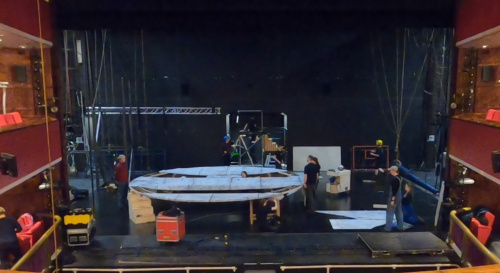

The moon is the largest set piece on this show. Its a 6m diameter frame made from an old revolve, which was layered with twin wall and painted cloth to create a 3D texture on the front face. There is also a double hinged door off centre left which required a balcony platform from behind to access.

This first photo shows the size of the moon in relation to the stage. Along with the scenic and construction departments working on it before rigging.

This second image below, shows the moon on the build truss, this was to allow LX to mount LED battons around the circumference before it was transferred to its final position which was too close to the theatre back wall to access with ladders.

The image to the right shows the moon hanging on its automation points infront of the balcony platform that comes in from the void. There is then a backcloth flown in behind on CW 29 which has a hole cut in it to access through to the moon.

Automated Movers

During the planning stages there was a requirement to move two moving lights IN/OUT to create a specific lighting effect on stage. We chose to use two BigTow winches to achieve this as it would give us the speed we needed but also the repeatably high accuracy every time. We also brought in black truss from NTS as when it flys in you can see the movers from the audience.

The effect desired was a physically moving beam of light, which then stays targeted on a single object centre stage. This then proved slightly harder than initially thought as when you press go on the auto cue, there is a period if time it takes to ramp up to the desired velocity and equally as is decelerates to come to a stop. The lighting programmer can plot a graph to which their cue runs to however we needed to know how long the acceleration and deceleration actually takes. We achieved this by plotting an AVD graph as seen below in Vectorworks, then using the tape measure tool to measure the length which equates to seconds.

I knew from the EpiQ desk that the accel was set to 1500mm/s^2. The velocity was 600mm/s. And the decel was set to 800mm/s^2. Total Cue time = 9.599s

So plotting a line from 0 (initial speed) to 1500mm over 1 second, then a constant at 600mm you can see where they intersect and draw a line down and measure from 0 again giving us 0.4 seconds. The same again for decel plotting 800mm over 1 second, intersection at 600mm, line down, measure to end of timed cue 9.599 seconds = 0.75s seconds. This plotted Trapezoid AVD graph is now to ramp up and down of that specific cue.

The LX programmer could then plot the exact same graph into the MA2 to achieve a smooth and linked* move.

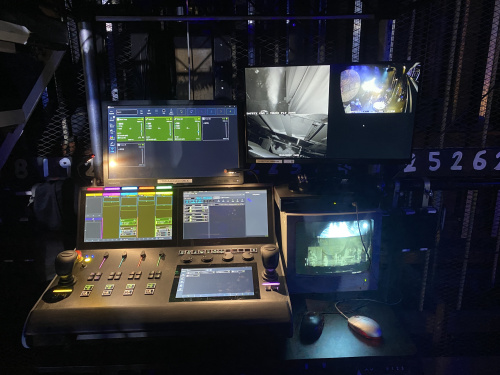

Auto Cameras

Due to the very busy wings on this show the automation desk couldn't go in a place with a clear line of slight of both automated set pieces. So it was positioned under the staircase that goes up to the USR platform. To overcome this issue we setup 3 serrate cameras around the set to monitor areas which might be affected when the set pieces are moving. The first (Top Right) is an overview of the stage, but facing predominately into the MSL wing as this is where the truss flys In to 1m. The second (Top Left) is a top down view of exactly where that truss is going to land, this is to make sure no-one or set is under it as it come to stage. The third (Bottom Left) is a camera placed above the moon balcony, this allows me to see that the doors on the moon are shut before it falls, and also to make sure that any crew of cast members are clear of it when quickly swoops away from the platform. Lastly in the bottom right I have a feed from show relay to give me a front on view of the stage. This also proved very useful to have backstage for other things other than auto!

Platforms

This show had a very 'climbable' set, almost everything was made or reinforced for acting on, from the large 4m platform USR to the tiny tin bins with stage weights and reinforced lids. This meant access to all these high areas had to be thought of and built into the offstage wing planning. At first when all the set was delivered to the stage most platforms were accessed via ladders, however once the large platform was in place the SM team decided some of the cast would find going up a ladder so high quite difficult under time pressure etc. Therefore we devised a large staircase method which you can see below.

The second image above is of the 'rolling get off platform' this is a truck that is never seen by the audience but rolls around the SR wing meeting the bedroom truck in whichever position it is in to provide access on and off the step which can been seen on stage. The angle of the bedroom truck also changed a lot so the rolling platform has a drawbridge that can be lowered to cover the gap created when the two don't meet flush.

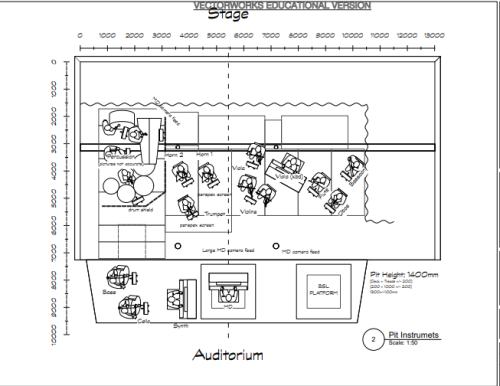

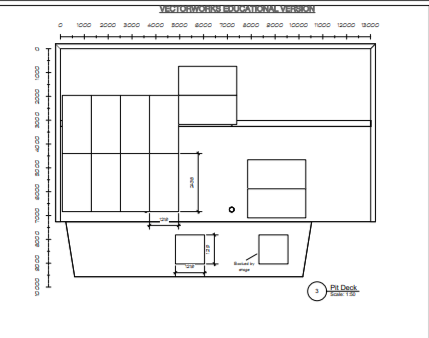

Ground Plans

Sound

Design

Comms

To connect our wired and wireless comms

- 3 Pin XLR out of wired comms basestation to in house patch

- From in house patch, XLR to 4-wire, into wireless comms basestation

To get wireless control pad

- Wireless basestation network settings

- Connect to basestations wifi

- Enter IP address in browser

Our settings

Meant that all wireless comms were constantly on B ring for our 'stage ring', but are still able to hear the DSM's show call.

Everyone on wired comms on A ring and are unable to hear wireless B ring.

B ring on wired comms was available too, separate wireless B ring, but are unable to hear the DSM.

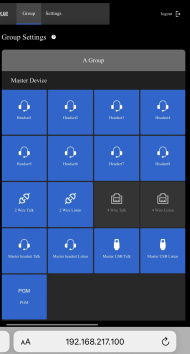

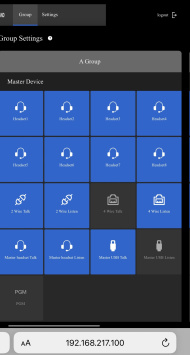

Hollyland Solidcom C1 HUB8S Control Pad

A Group - Default  B Group - Default

B Group - Default

A Group - Changed  B Group - Changed

B Group - Changed

Equipment and Power

Pit: Uses of power = 13amp and 16amp. Our DQ rack which distrobutes signal to the digico desk is powered by 16amp found in the upsatge left corner of the pit. we postioned our DQ rack at the front of the pit, DSL. This was because we had four subs on this show, two B1 - L + R and two C7 Subs - L + R. these were powered by amplifiers inserted in our DQ rack in the pit. We avoided long unwated runs of NL4(speaker cable) and were able to concentrate all of our cable runs at the front of the pit where easily accesible and out of the way of band memebers.

Nineteen microphones were used in our pit band. Microphone types included: DPA 4099 - Violins, Violas, Bass, Cello which were all attached using specific clips designed for each instruments. For example a violin clip:

Piccolo Snare Drum - AT2020 Snare Drum - AT2020 Bass Drum - SM89 Tom-toms - SE300 Cymbal (Suspended) - SE300 Small Choke Cymbal- SE300 Horn I - beta 57 Horn II - beta 57 Trumpet - MD441

Each instruments microphone is connected to the DQ rack in the inputs section via XLR cable. Once connected the digico SD12 in use is able to pick up their signal via dnate network. We used three stage boxes around the pit in order to control the amount of cable needed. See Image below.

Our main cable run was along the front of the situated steel deck we used bungies to attach the cables to the steel rungs. This was because it is fast and easy to attach, adjust-access cable, strike and is much more environmentally friendly than tape. The cables consisted of XLR, Cat 5 ethernet and power for our stage boxes

Some instruments it made sense to hang mics,The infrastructure of the pit allowed us to easily hang mics. See image below:

Pit PLan:

We layed black painted steel deck, this blacked out the grey floor in the pit, allowed us to manage cable runs better and added a certain elegance to the pit. We also rigged a black drape around the back of the pit to cover any unwanted storage.

In order for each band member to essentially have their own foldback we used a behringer powerplay system, beheinger base station connected to two distrobuters which distrobuters to each musicians powerplay unit, this small P16-M mixer allowed the musicician to switch between different groups within the mix. for example, strings Vox etc. Adjust volumes, pan, add effects etc. Headphones were required.