What I Meant Was...: Difference between revisions

| (One intermediate revision by the same user not shown) | |||

| Line 68: | Line 68: | ||

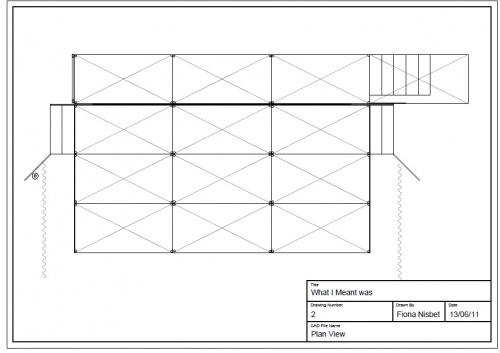

[[Image:WIMW Plan.jpg|center|500px]] | [[Image:WIMW Plan.jpg|center|500px]] | ||

[[Image:WIMW End On.png|center|500px]] | |||

==Technical Challenges== | ==Technical Challenges== | ||

| Line 80: | Line 82: | ||

Originally, the designer wanted the masking around the frame to be hard masking, but this was going to be too expensive, so was changed to soft. The masking and the gauze had to be very close together for the projection, to the top border, legs, and the gauze were all put on the same bar. This gave us no play with the legs however, as they did not reach the ground when the bar was grided. This problem was solved by hanging a short piece of scaff from each end of the bar, and putting piece of rope through the scaff and tying it onto the counter weight bar, which meant that the bar would self level itself and the leg would always sit straight. For the masking on the bottom of the frame, hard masking was used, which was kept in place by screwing it to the steel deck. | Originally, the designer wanted the masking around the frame to be hard masking, but this was going to be too expensive, so was changed to soft. The masking and the gauze had to be very close together for the projection, to the top border, legs, and the gauze were all put on the same bar. This gave us no play with the legs however, as they did not reach the ground when the bar was grided. This problem was solved by hanging a short piece of scaff from each end of the bar, and putting piece of rope through the scaff and tying it onto the counter weight bar, which meant that the bar would self level itself and the leg would always sit straight. For the masking on the bottom of the frame, hard masking was used, which was kept in place by screwing it to the steel deck. | ||

[[Image:WIMW Iso.png|center|500px]] | |||

Latest revision as of 21:20, 14 June 2011

| What I Meant Was... | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||

What I Meant Was...

| ||||||||||||||||

What I Meant Was... is a drama piece of 8 short American plays, which is being performed at the Tron Theatre Glasgow.

Production Team

Production Manager Sandy McRobbie

Stage Manager Catherine Lewis

Deputy Stage Manager Laura Jarvis

Assistant Stage Manager James Gow and Sean Hind

Lighting Designer Ian Swinscoe

Sound Designer Jonny Reed

Production Electrician Craig Ralph

Technical Stage Manager Fiona Nisbet

Lighting Operator Fiona Findlater

Sound Operator Michael Parkin

Lighting Crew Suzie Inglis and Sophie Martin

Technical Crew Jade Beatson and John Beggan

Set

The set consisted mainly of steel deck, with a different height at the back. This was behind a white gauze, surrounded by black masking to create a frame. This was then projected onto with different images and clips for each play.

Technical Challenges

Washing Line

During 'Action' a washing line needed to be in place US, 3 metres high. The original idea was to have two pieces of scaff at 2500mm, attach a scaff foot to one end and a screw jack to the other and place one in each wing. Once they were in place they could then be tightened between the floor and the bottom of the fly floor. On SR, a clamp with an eye on it would then be attached to the top of the bar, and on the other side a cleat to keep the washing line tight. From each of these points, on both sides, black sash would be tied on and attached to a pulley. The washing line would then go through the pulley so that the actors could stand on a chair and move the washing line on stage.

This plan ended up not being right however, as the ceiling in the wings is only plaster board and not strong enough. In the SR wing there was a beam in the ceiling, so we could still use the idea on one side. For the other we ended up using a hook attached to a snap hook with some sash, which during the scene change would be connected to the washing line pulley that had a snap shackle. However, because the hook on SL was lower than the point SR it sat at an odd angle onstage and another line had to dropped from the fly floor and the snap hook attached to that as well. So during the scene change, I would pass an actor on stage the pulley, it would be taken across the stage and hook to the snap hook hanging from the fly floor.

Gauze and Frame

Originally, the designer wanted the masking around the frame to be hard masking, but this was going to be too expensive, so was changed to soft. The masking and the gauze had to be very close together for the projection, to the top border, legs, and the gauze were all put on the same bar. This gave us no play with the legs however, as they did not reach the ground when the bar was grided. This problem was solved by hanging a short piece of scaff from each end of the bar, and putting piece of rope through the scaff and tying it onto the counter weight bar, which meant that the bar would self level itself and the leg would always sit straight. For the masking on the bottom of the frame, hard masking was used, which was kept in place by screwing it to the steel deck.