Quick release tension wire system: Difference between revisions

SMacluskie (talk | contribs) No edit summary |

SMacluskie (talk | contribs) No edit summary |

||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Projects]] | |||

[[Category:Production Projects]] | |||

Having moved a | This page documents the solution by [[Kirsty Campbell]] to the production challenge of rigging a quick release tension wire system for the production of [[The Seagull]] in the New Athenaeum Theatre , November 2009. | ||

Initial attempts at constructing this included using a [http://www.highgearsales.com/TIRFOR1.jpg Tirfor] which as expected turned out to be far too loud to de-rig during a short scene change. After much deliberation, it was decided that the most effective method involved using an automation winch to create the desired effect. | |||

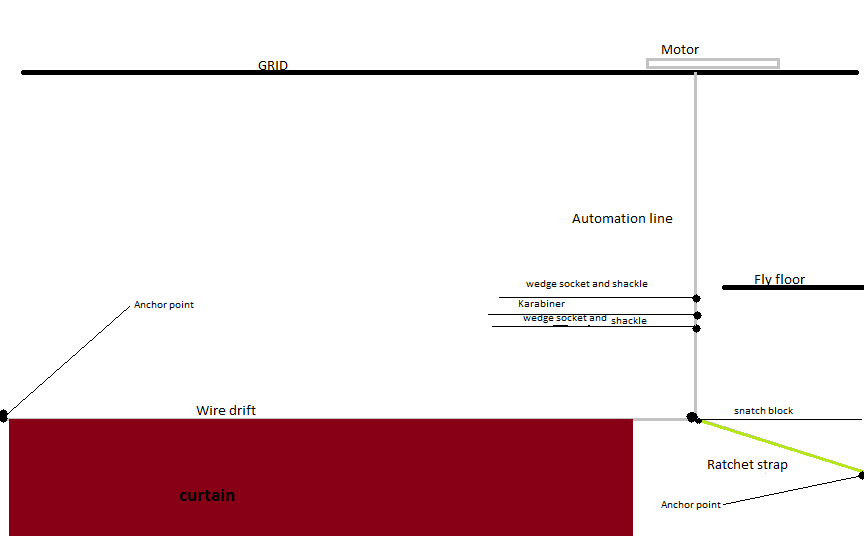

Having moved a winch to the desired position, we then lowered the line to meet a 15metre wire drift and attached the two with wedge sockets and shackles. we also added a karabiner between the two lines in order to make the release time quicker and simpler. At a lower point in the line (the same height as the top of the curtain a snatch block was used to divert the direction of the line. A ratchet strap was attached to the snatch block and anchored to a scaff bar at a 45 degree angle which would maintain the horizontal position of the line. | |||

[[Image:tension wire picture.png]] | [[Image:tension wire picture.png]] | ||

Latest revision as of 13:23, 7 December 2012

This page documents the solution by Kirsty Campbell to the production challenge of rigging a quick release tension wire system for the production of The Seagull in the New Athenaeum Theatre , November 2009.

Initial attempts at constructing this included using a Tirfor which as expected turned out to be far too loud to de-rig during a short scene change. After much deliberation, it was decided that the most effective method involved using an automation winch to create the desired effect.

Having moved a winch to the desired position, we then lowered the line to meet a 15metre wire drift and attached the two with wedge sockets and shackles. we also added a karabiner between the two lines in order to make the release time quicker and simpler. At a lower point in the line (the same height as the top of the curtain a snatch block was used to divert the direction of the line. A ratchet strap was attached to the snatch block and anchored to a scaff bar at a 45 degree angle which would maintain the horizontal position of the line.