Tilting trellis pieces: Difference between revisions

SMacluskie (talk | contribs) No edit summary |

SMacluskie (talk | contribs) No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Projects]] | [[Category:Projects]] | ||

These Tilting Trellis pieces were part of the production [[The Seagull]] in the New Athenaeum Theatre, November 2009. | [[Category:Production Projects]] | ||

These Tilting Trellis pieces were part of the production [[The Seagull]] in the New Athenaeum Theatre, November 2009. The Technical Stage Manager was [[Kirsty Campbell]] | |||

This was required to be a live move which was cued and specifically timed. Throughout the production period there were a few solutions that were considered. Each trellis piece was over 6 meters tall and 300 mm wide. The trellis was made from box steel and although it was lightweight it was also extremely flexible, this also affected the way we could hang and handle the pieces. | This was required to be a live move which was cued and specifically timed. Throughout the production period there were a few solutions that were considered. Each trellis piece was over 6 meters tall and 300 mm wide. The trellis was made from box steel and although it was lightweight it was also extremely flexible, this also affected the way we could hang and handle the pieces. | ||

Latest revision as of 08:55, 4 December 2012

These Tilting Trellis pieces were part of the production The Seagull in the New Athenaeum Theatre, November 2009. The Technical Stage Manager was Kirsty Campbell

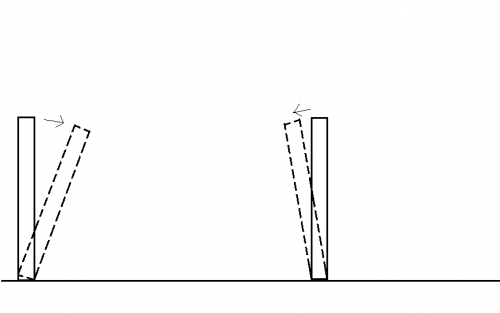

This was required to be a live move which was cued and specifically timed. Throughout the production period there were a few solutions that were considered. Each trellis piece was over 6 meters tall and 300 mm wide. The trellis was made from box steel and although it was lightweight it was also extremely flexible, this also affected the way we could hang and handle the pieces.

We started by hanging the trellis from the top of the structure. Having found an effective way to attach the hardware we initially decided to to hang the pieces vertically on spot lines.This next picture shows how we attached the hardware. First we measured down 300 mm from the top of the trellis and drilled a hole through the box steel front to back. As a bolt was passed through the hole it was also passed through a 1 meter sling. To the other end of the sling we attached our shackle and drift to which we tied on our hemp lines. Two vertical lines were required for each trellis piece.

Although this method kept the pieces vertically straight it allowed for very little horizontal movement which was critical for the tilting effect. To remedy this we added two horizontal lines to each trellis which were cleated off on each fly floor. This method provided sufficient horizontal force to tilt the pieces and hold them in place.

This picture shows how the horizontal hemp lines were attached to the trellis pieces and how the lines tightened/expanded to tilt the trellis.